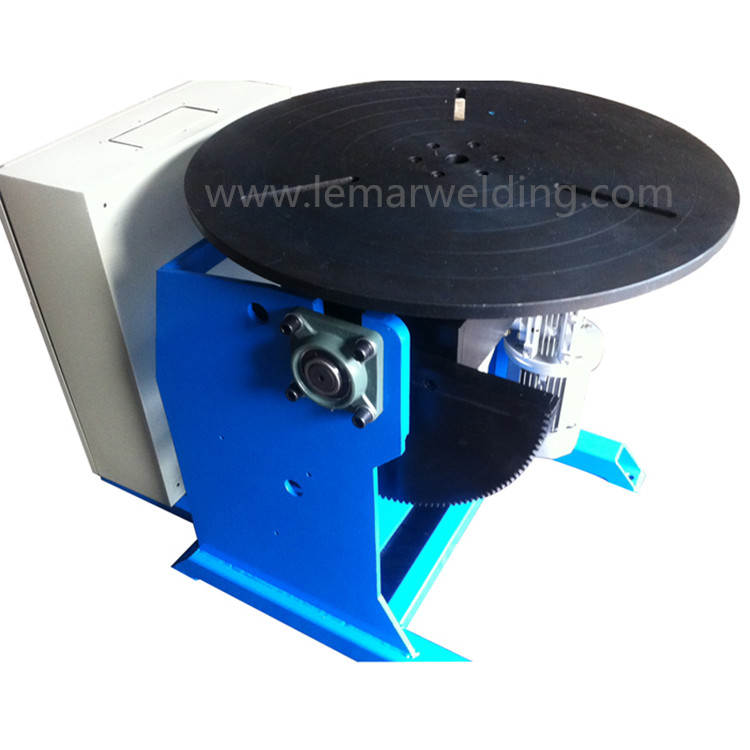

Lemar is mainly engaged in the research and development, manufacturing and sales of CNC cutting machines, welding roller frames, welding manipulators, welding positioners, wind turbine tower production lines, H-beam production lines, surfacing equipment, plasma welding equipment, etc.

Products are widely used in boilers, pressure vessels, petrochemicals, power stations, machinery, ships, wind power, steel structures and other industries

Lemar is mainly engaged in the research and development, manufacturing and sales of CNC cutting machines, welding roller frames, welding manipulators, welding positioners, wind turbine tower production lines, H-beam production lines, surfacing equipment, plasma welding equipment, etc. Products are widely used in boilers, pressure vessels, petrochemicals, power stations, machinery, ships, wind power, steel structures and other industries

Classification of automatic welding equipment

In the past 20 years, with the improvement of design requirements and the high emphasis on welding quality, automatic welding has developed into an advanced manufacturing technology, and automatic welding equipment has played an increasingly important role in the application of various industries. In modern industrial production, the mechanization and automation of the welding production process is the inevitable trend of the modern development of the welding mechanism manufacturing industry.

According to the degree of automation, automated welding equipment can be divided into the following three categories:

1)Rigid automatic welding equipment Rigid automatic welding equipment can also be called primary automatic welding equipment, most of which are designed according to the principle of open-loop control.

Although the entire welding process is automatically completed by the welding equipment, the closed-loop feedback system cannot be used for the fluctuation of welding parameters during the welding process, and the possible deviations cannot be corrected randomly.

2)Adaptive control of automatic welding equipment

The self-adaptive control welding equipment is a kind of welding equipment with a high degree of automation. It is equipped with sensors and electronic detection circuits to automatically guide and track the welding seam trajectory, and implement closed-loop feedback control of the main welding parameters. The entire welding process will be automatically completed according to the pre-set procedures and process parameters

3)Intelligent automatic welding equipment

It uses a variety of advanced sensor elements, such as vision sensors, tactile sensors, auditory sensors and laser scanners, etc., and with the help of computer software systems, databases and expert systems with recognition, judgment, real-time detection, calculation, automatic programming, welding parameters The function of storing and automatically generating welding record files.