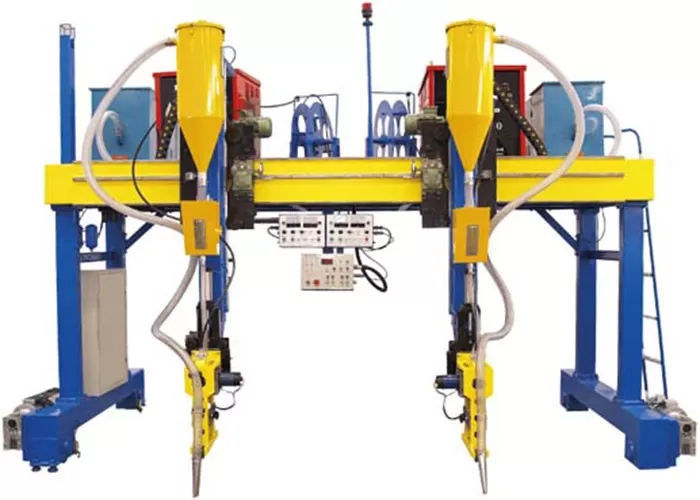

1. The production of welding H-shapedbeam steel is to place the H-shaped steel in an "I" shape, and weld two corner seams on both sides at the same time, which greatly increases the welding efficiency. Due to the symmetrical welding, the web is basically not deformed after welding.

2. Orthopedic mechanism H-shaped steel flange straightening machine realizes the direct correction of the angular deformation of the hot H-shaped steel wing plate after butt welding through the eccentric pressing roller, which reduces the correction force and improves the correction accuracy.

3. From the perspective of welding specifications, the specifications for welding H-beams are the largest in China, and are the same as the H-beam welding production line of the most advanced H-beam welding equipment production company (ESAB) abroad.

4. In the assembly method, the assembly-welding integrated method is adopted, which reduces the process and improves the production efficiency.

5. In the centering method of the web and flange plates, two groups of front and rear centering methods are adopted to improve the positioning accuracy.

6. The wire feeder is softly connected to the welding torch and the welding angle of the torch can be adjusted.

7. Large fillet welding seam adopts dual power (DC+AC) dual wire, dual arc, and dual molten pool welding process. These features of this production line are the first in China.

8. It adopts imported PLC control, which is reliable and easy to program.

9. At the same station, continuously complete all the processes of assembly, welding, correction, lifting, and discharging of H-shaped steel in the production process.

Lemar Machinery is mainly engaged in the research and development, manufacturing and sales of CNC cutting machines, welding roller frames, welding manipulators, welding positioners, wind turbine tower production lines, H-beam production lines, surfacing equipment, plasma welding equipment, etc. Products are widely used in boilers, pressure vessels, petrochemicals, power stations, machinery, ships, wind power, steel structures and other industries.