Longitudinal seam welding machine is a kind of high quality, high efficiency, no deformation to complete the wall thickness of 0.5 mm-6 mm thin wall cylinder, conical cylinder, flat plate or one end open square box butt longitudinal seam welding equipment.

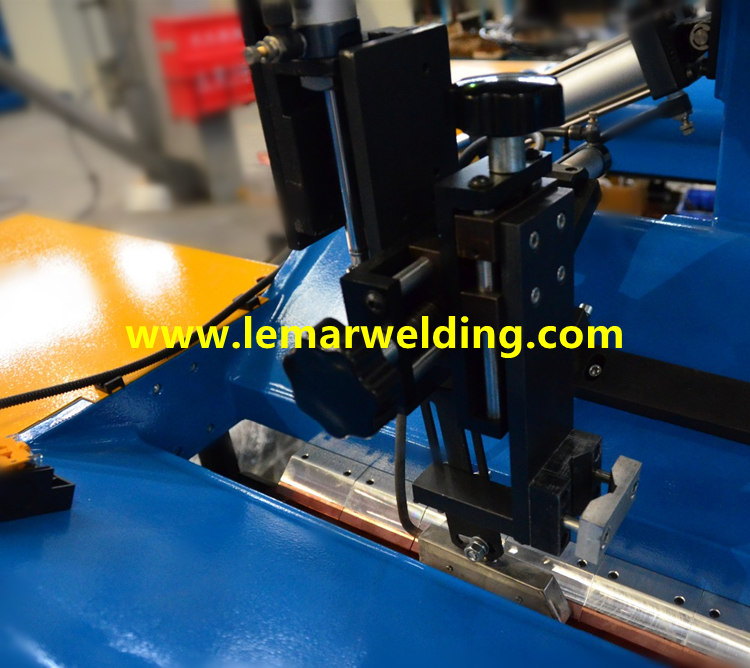

Pneumatic keyboard pressing structure, closely arranged along both sides of the straight seam, to ensure that the butt weld is evenly pressed in the whole welding length range; The spacing between left and right keys can be adjusted to adapt to welding of different parts (flat plate splicing and longitudinal seam welding of cylinder).

The welding mandrel provides the function of weld back air protection; According to the cylinder or plate work-piece processing different welding groove, to achieve single-side welding double-side molding.

The traditional technology generally adopts SAW PAW MAG TIG and MIG welding.