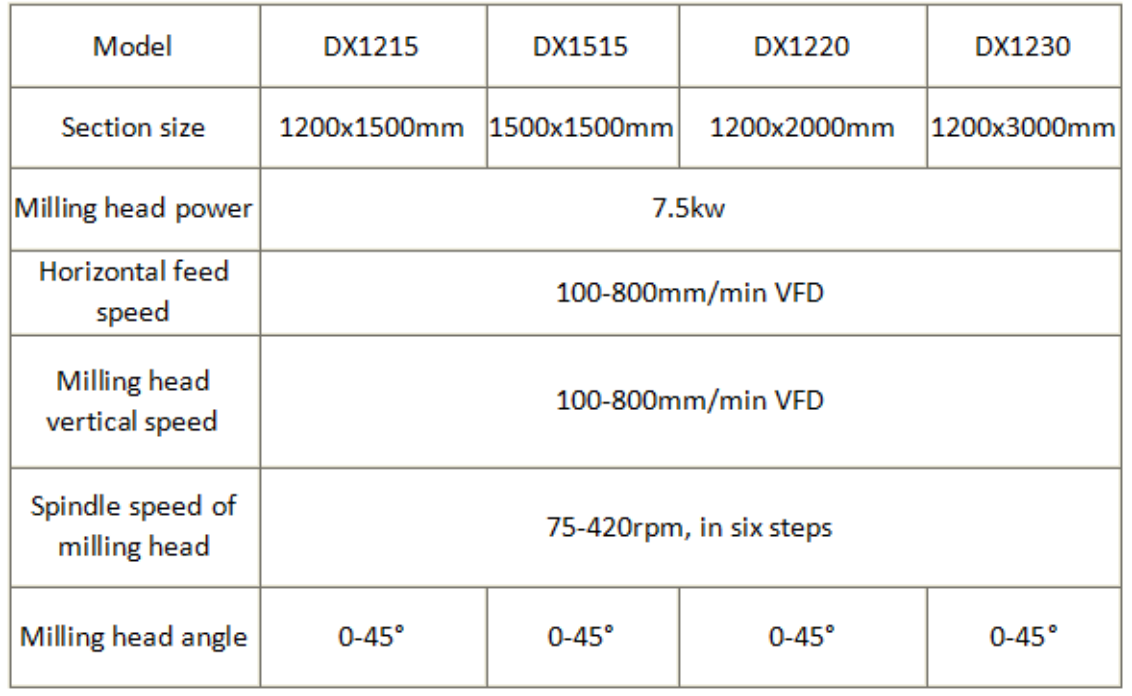

The machine is used for welding or rolling shaped H-shaped steel or BOX steel, end milling processing, can milling the maximum work-piece end face of 2000×1500 mm, the minimum work-piece end face of 300×200 mm steel.

The machine has the advantages of easy operation, simple structure and quick adjustment, etc. It is one of the necessary equipment for welding section steel manufacturers.

Scope of supply and component units

Rise and fall pillar

Including: 1 milling head, lifting slide plate, lifting column, lifting transmission mechanism and Angle adjustment mechanism, etc.

Horizontal slide table includes: slide table, bed, transmission mechanism, rack and pinion, etc.

Electric control system includes: electric control box, system box, operation box, NUMERICAL control system, AC servo drive system, circuit system, etc.

Hydraulic support: 1 group, including: cylinder, work bench, cylinder seat, hydraulic station, etc.

1 set of milling cutter, including: φ 200 face milling cutter (10 teeth), blade.

Accessories: 1 set, including: knife tray pull rod, knife mounting tool.