The intermediate frequency induction furnace uses an intermediate frequency power supply to establish an intermediate frequency magnetic field, which induces eddy currents and heat generation in the ferromagnetic material, so as to achieve the purpose of heating the material.

The intermediate frequency heating furnace adopts 200-2500HZ intermediate frequency power supply for induction heating, smelting and heat preservation.It is mainly used for smelting carbon steel, alloy steel, special steel, and can also be used for smelting and raising temperature of non-ferrous metals such as copper and aluminum.

The IF induction furnace manipulatoris used in the intermediate frequency induction furnace steel making workshop of the steel plant, and is installed between the two furnace shells.

It is small in size, light in weight, high in efficiency, low in power consumption, fast in melting and heating, easy to control the furnace temperature, and high in production efficiency.

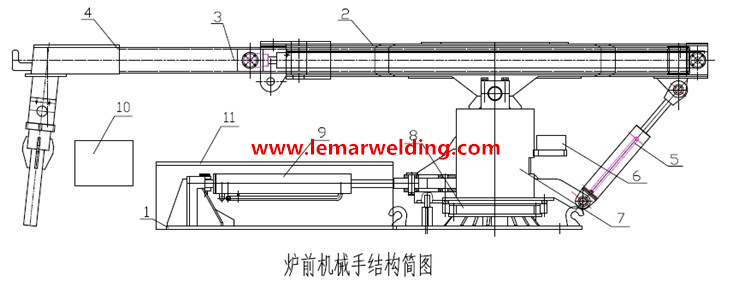

Schematic diagram

No. | Name |

1 | Base |

2 | Outer beam |

3 | Push-pull cylinder |

4 | Inner beam |

5 | Lifting cylinder |

6 | Oil circuit block assembly |

7 | Rotating column assembly |

8 | Slewing support |

9 | Rotating cylinder |

10 | Hydraulic station |

11 | Protective cover |

Main technical parameters(Can customize according to buyer’s need)

No. | Item | Note |

1 | Rotation range | -86°~86 ° |

2 | Telescopic stroke | 0~3300mm |

3 | Stroke of lifting pressure mechanism | +1500~ -1200mm |

4 | Manipulator height | 1300 ~ 1600mm |

5 | Base width | 1150~ 1350mm |

6 | Base length | 2000~ 3300mm |

7 | Range of telescopic boom length | 5100 ~ 8500mm |

8 | Push-pull torque | 0 ~ 5T |

9 | Down pressure torque | 0 ~ 4T |

10 | Rotating torque | 0 ~ 3T |

11 | System pressure range | 0~16Mpa |